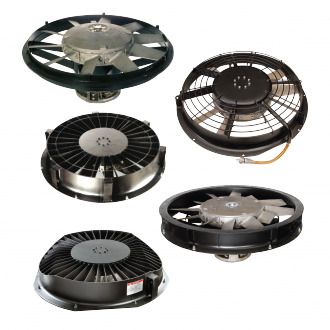

Vaneaxial Fans and Assemblies

Dayton-Phoenix Group motor and fan components are designed to withstand torque changes and multiple starts, with heavy, custom fabricated rolled-steel frames, Class H insulation, and zinc-plated hardware. The motor bearing support systems are specifically designed to withstand high temperature operation for extreme long life. The fans incorporate unique inside-out motors that provide more horsepower in a smaller package than commercially designed motors. All motors are performance tested under load and undergo vibration analysis prior to shipping. Dayton-Phoenix Group builds all motor sub-assemblies in-house to close dimensional tolerances for superior quality control.

Advantages & Features

- OEM Supplier

- Built to withstand extreme conditions

- All motor sub-assemblies are built in-house to close dimensional tolerances and quality control, with commutators custom built to your motor’s specifications

- Dynamic, two-plane balance for high-speed, smooth, and virtually vibration-free operation

- Exceeds OEM maintenance overhaul schedules

- Up to 75,000 CFM

- Motors ranging from 18–105 HP, 200–682 V and 60–133 Hz

Applications

- Locomotive Cooling Fans

- Dynamic Braking Grid Fans

- Locomotive

- Mining - Power Generation Cooling